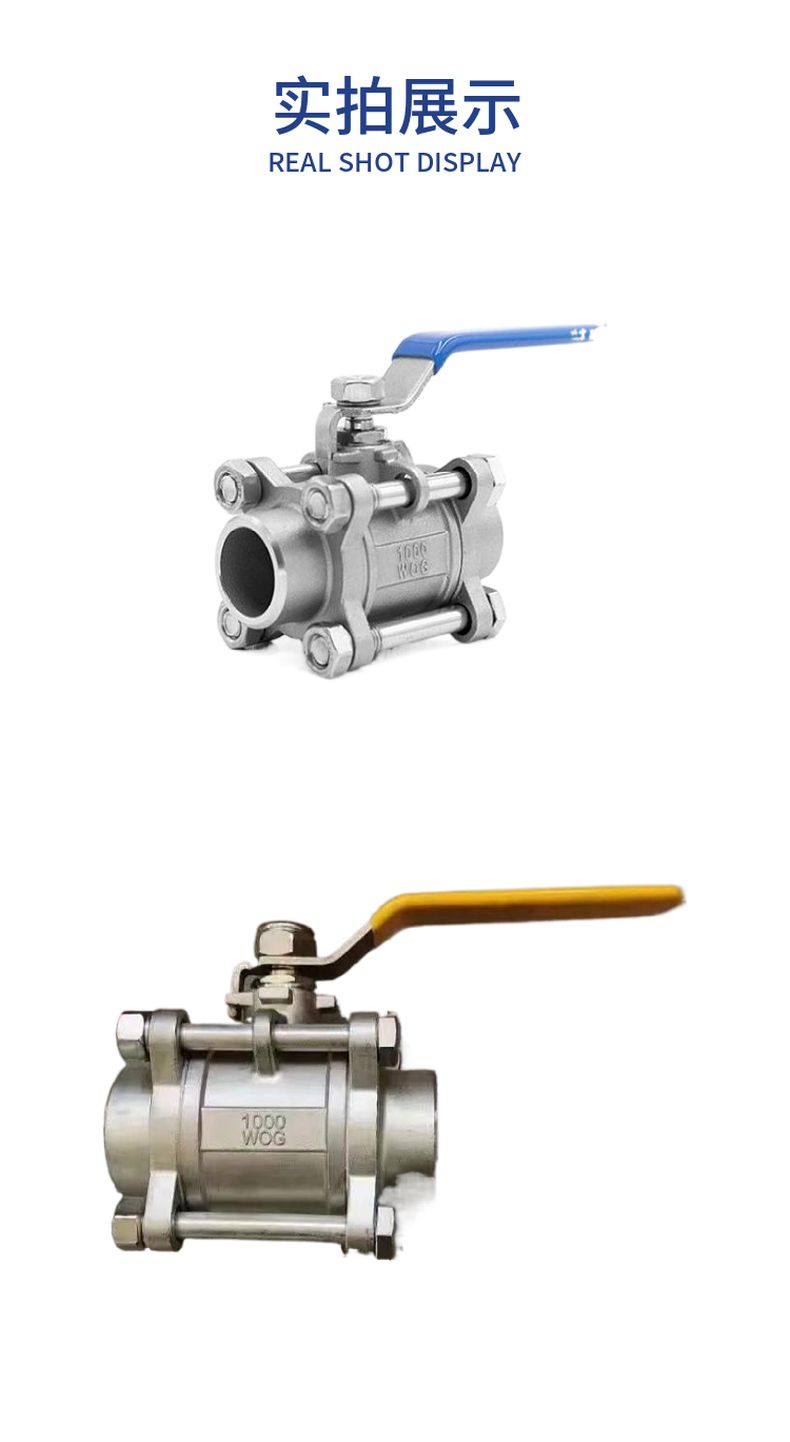

Q11F three-piece butt welding ball valve

Ball valves and butt welded ball valves are divided into integral one-piece, two-stage and three-stage types. Valve body casting using the advanced technology introduced in Taiwan, reasonable structure, beautiful shape. The valve seat adopts elastic sealing structure, reliable sealing, easy opening and closing. The valve stem adopts the down-mounted structure with reverse seal, and the valve stem will not be rushed out when the abnormal pressure is raised in the valve chamber. Two piece, three piece ball valve connection forms have butt welding (BW) socket welding (SW), and can be equipped with international standard ISO support platform and locking device. Can be set 90° switch positioning mechanism, according to the need to lock to prevent misoperation, driving mode: manual, electric, pneumatic. Choose different materials, can be applied to water, steam, oil, nitric acid, acetic acid and other media. Internal thread connection ball valve and butt welding connection ball valve are suitable for PN1.0 ~ 4.0MPa, working temperature -29 ~ 180ºC(sealing ring for enhanced polytetrafluoroethylene) or -29 ~ 300ºC(sealing ring for para polystyrene) of various pipelines, used to cut off or connect the medium in the pipeline.

Q11F three-piece ball valve main connection size and weight

Q11F three piece ball valve main parts materials